Product List

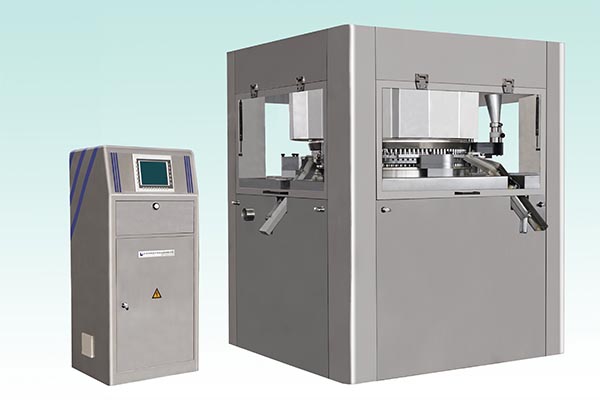

GZPT Tablet Press

Description

GZPT-1060 series automatic triple rotary tablet press can finish the process three times in one rotation of turret, including filling, dosing, prepressing, pressing and ejecting. Developed in 2009, GZPT-1060 tablet press is a kind of large scale tablet press developed on the basis of years of experiences. This triple rotary tableting machine adopts modular structure design. Major components of this machine including track, main-press roller, pre-compression roller, feeder and dosing device are easy to dismantle, clean and maintain. GZPT tablet press fully meets GMP requirements and is capable of producing double- and three-layer tablets, as well as round, irregular, engraved and annular tablets.

Advantages

1. Electrical control mechanism adopts B&R PCC (program-controlled computer). Compared with traditional PLC (programmable logic controller), it owns stand-out performance in CPU frequency, data storage, scan cycle, programmed language and calculation speed.

2. With fast production speed and high efficiency, this triple rotary tableting machine can make three tablets in one rotation of turret. Compared with double-sided tablet press, its production efficiency increases by 50% and highest output reaches 1.5 million per hour.

3. As main-press roller structure is the same with pre-compression roller structure, diameters of both press rollers are 250 millimeters. Every tablet has been compressed for two times. Thus product quality can be ensured with long shaping time.

4. Capable of producing single-, double- and three-layer tablets, our triple rotary tableting machine can be applied to a large production scope.

Features

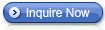

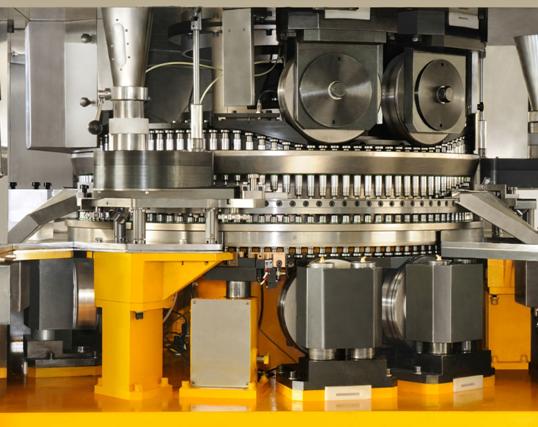

1. Rigid four-column structure helps to offset forces in operation, ensuring machine can run stably with low center of gravity.

2. Traditional hydraulic system is replaced with strong supporting system to help triple rotary tableting machine to avoid oil leakage, thus preventing tablets from being contaminated.

3. Dosing mechanism and lower roller mechanism can be adjusted through worm gear mechanism by motor, and adjustment precision can reach 0.01 millimeters. Operator can adjust two mechanisms by setting value on the touch screen or by transferring parameters already saved. In this way, it’s easy to make adjustment and loss of powder can be reduced during adjustment.

4. Main-press roller structure is the same with pre-compression roller structure (250 mm). Both pressure can reach 100 kN and can be displayed on the touch screen.

5. When pressing oval tablet or concave tablet, large pre-pressure ensures air in the powder can be well pressed out before tablet is shaped, thus reducing possibility of tablet breakage.

6. If main-press roller is broken incidentally, it can be exchanged with pre-compression roller until new roller arrives so that production can still continue.

7. Both main pressure and pre-pressure sensors are LCD-22.7Ttt from TEDEA, Germany, which can precisely and directly detect the pressure, thus ensuring the pressure is stable and easy to test.

8. Our automatic triple rotary tablet press is equipped with modular cam track.

9. Triple impeller force-feed device controls the flow of powder and ensures the accuracy of feeding.

10. This machine adopts automatic central lubrication system.

11. Electric control system is entirely separated from main machine. This design can extend the service life of electric control system.

12. Users can set different passwords for safe operation.

13. This equipment adopts automatic tablet weight control system.

14. Technological parameters can be saved and invoked, which reduces adjustment time.

Application

1. GZPT tablet press is mainly used in pharmaceutical, chemical and food industry.

2. Automatic triple rotary tablet press is capable of producing single-, double- and three-layer tablets, as well as round, irregular, engraved and annular tablets.

3. Our automatic triple rotary tablet press can press particles at the mesh size from 12 to 60 and with good compressibility and fluidity.

4. The triple rotary tableting machine can press the synthetic medicine which is uniform, dry and with fine granules less than a third of granules.

5. Our equipment can press dry traditional Chinese medicine.

Parameters

GZPT-1060 series automatic triple rotary tablet press can finish the process three times in one rotation of turret, including filling, dosing, prepressing, pressing and ejecting. Developed in 2009, GZPT-1060 tablet press is a kind of large scale tablet press developed on the basis of years of experiences. This triple rotary tableting machine adopts modular structure design. Major components of this machine including track, main-press roller, pre-compression roller, feeder and dosing device are easy to dismantle, clean and maintain. GZPT tablet press fully meets GMP requirements and is capable of producing double- and three-layer tablets, as well as round, irregular, engraved and annular tablets.

Triple-sided feeding, tablet pressing and ejecting

Advantages

1. Electrical control mechanism adopts B&R PCC (program-controlled computer). Compared with traditional PLC (programmable logic controller), it owns stand-out performance in CPU frequency, data storage, scan cycle, programmed language and calculation speed.

2. With fast production speed and high efficiency, this triple rotary tableting machine can make three tablets in one rotation of turret. Compared with double-sided tablet press, its production efficiency increases by 50% and highest output reaches 1.5 million per hour.

3. As main-press roller structure is the same with pre-compression roller structure, diameters of both press rollers are 250 millimeters. Every tablet has been compressed for two times. Thus product quality can be ensured with long shaping time.

4. Capable of producing single-, double- and three-layer tablets, our triple rotary tableting machine can be applied to a large production scope.

Features

1. Rigid four-column structure helps to offset forces in operation, ensuring machine can run stably with low center of gravity.

2. Traditional hydraulic system is replaced with strong supporting system to help triple rotary tableting machine to avoid oil leakage, thus preventing tablets from being contaminated.

3. Dosing mechanism and lower roller mechanism can be adjusted through worm gear mechanism by motor, and adjustment precision can reach 0.01 millimeters. Operator can adjust two mechanisms by setting value on the touch screen or by transferring parameters already saved. In this way, it’s easy to make adjustment and loss of powder can be reduced during adjustment.

4. Main-press roller structure is the same with pre-compression roller structure (250 mm). Both pressure can reach 100 kN and can be displayed on the touch screen.

5. When pressing oval tablet or concave tablet, large pre-pressure ensures air in the powder can be well pressed out before tablet is shaped, thus reducing possibility of tablet breakage.

6. If main-press roller is broken incidentally, it can be exchanged with pre-compression roller until new roller arrives so that production can still continue.

7. Both main pressure and pre-pressure sensors are LCD-22.7Ttt from TEDEA, Germany, which can precisely and directly detect the pressure, thus ensuring the pressure is stable and easy to test.

8. Our automatic triple rotary tablet press is equipped with modular cam track.

9. Triple impeller force-feed device controls the flow of powder and ensures the accuracy of feeding.

10. This machine adopts automatic central lubrication system.

11. Electric control system is entirely separated from main machine. This design can extend the service life of electric control system.

12. Users can set different passwords for safe operation.

13. This equipment adopts automatic tablet weight control system.

14. Technological parameters can be saved and invoked, which reduces adjustment time.

Application

1. GZPT tablet press is mainly used in pharmaceutical, chemical and food industry.

2. Automatic triple rotary tablet press is capable of producing single-, double- and three-layer tablets, as well as round, irregular, engraved and annular tablets.

3. Our automatic triple rotary tablet press can press particles at the mesh size from 12 to 60 and with good compressibility and fluidity.

4. The triple rotary tableting machine can press the synthetic medicine which is uniform, dry and with fine granules less than a third of granules.

5. Our equipment can press dry traditional Chinese medicine.

Parameters

| Model | GZPT-76 | GZPT-95 | GZPT-113 | GZPT-122 |

| No. of Stations | 76 | 95 | 113 | 122 |

| Punch Type | D | B | BB | BBS |

| Max. Output (tablets/hour) | 697000 | 872000 | 1037000 | 1500000 |

| RPM | 5.1 to 51 | 6.8 to 68 | ||

| Max. Main Pressure (kN) | 100 | |||

| Max. Pre-pressure (kN) | 100 | |||

| Max. Filling Depth (mm) | 20 | 16 | 16 | 16 |

| Range of Tablet Thickness (mm) | 1 to 8.5 | |||

| Max. Tablet Diameter (mm) | 25 | 16 | 13 | 11 |

| Max. Length of Irregular Tablet (mm) | 25 | 19 | 16 | 13 |

| Punch Diameter (mm) | 1060 | |||

| Main Motor Power (kW) | 18.5 | |||

| Weight (kg) | 8000 | |||

| Dimension (mm) | 1720 × 1720 × 2182 | |||

English

English Russian

Russian Spanish

Spanish French

French